If you’re running a business that involves selling products, then product data management is something that you need to consider. It’s the process of collecting, organizing, and analyzing product data to make informed decisions and improve business operations. In this article, we’ll discuss everything you need to know about product data management, including its importance, pros and cons, alternatives, step-by-step guide, tips, and more.

What is Product Data Management?

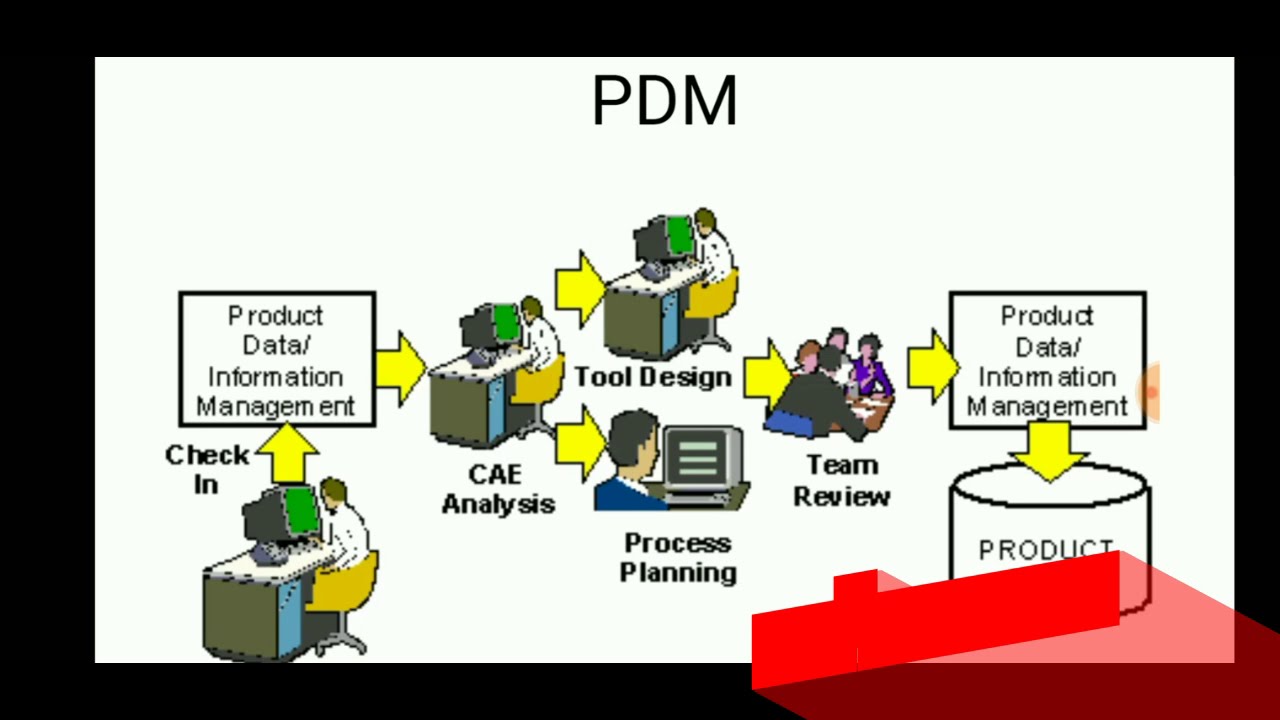

Product data management (PDM) is the process of managing the information related to products in your business. This information can include product descriptions, specifications, pricing, images, and other relevant details. PDM is not just about data storage but more of a comprehensive approach to manage data throughout the product lifecycle.

Why is Product Data Management Important?

- Better Decision-Making: Having accurate and complete product data helps you make informed decisions about pricing, marketing, and inventory management.

- Improved Efficiency: Centralizing product data eliminates time-consuming manual processes such as data entry and reduces errors.

- Enhanced Customer Experience: Accurate and detailed product information can improve customer satisfaction and reduce returns.

- Regulatory Compliance: Maintaining accurate records of product information can help ensure compliance with regulations and standards.

- Competitive Edge: Effective PDM can help businesses gain a competitive edge by quickly adapting to market changes and offering new products.

Pros and Cons of Product Data Management

Pros:

- Increased efficiency

- Improved decision-making capabilities

- Better customer experience

- Enhanced data accuracy

- Greater regulatory compliance

Cons:

- High initial investment

- Requires ongoing maintenance and updates

- Time-consuming implementation process

- May require specialized training for employees

- Inadequate data security measures can lead to breaches

Alternatives to Product Data Management

While PDM is the most effective way to manage product data, here are some alternatives to consider:

Rearchitecting for the cloud ought to embrace containerization of main software elements in one thing like Docker, which may then be managed by an open sourced Kubernetes orchestration framework for optimization of assets and effectivity. We anticipate that containerization will finally be the defacto normal for working workloads within the cloud, and never simply the wrapped up monolithic app implementations introduced over from consumer server implementations.

- Spreadsheets: A spreadsheet can be used to store and organize product information. However, it’s not a scalable solution and prone to errors.

- Paper-Based Systems: Some businesses still use paper-based systems to manage product information. It’s time-consuming, error-prone, and difficult to scale.

- Enterprise Resource Planning (ERP) software: ERP software is a comprehensive solution that includes PDM and other business functions such as accounting, HR, and supply chain management. However, it requires a significant investment and may be too complex for some businesses.

How to Implement Product Data Management

Here are the steps to implement effective PDM in your business:

“An enormous want to maneuver to the cloud, and stress from strains of enterprise to maneuver to the cloud, have created an expertise hole that has led to severe missteps and compelled IT groups to repatriate workloads that they had put within the cloud again into the information middle,” says Scott Sinclair, senior analyst at IT analysis agency ESG. “IT’s degree of competence, expertise, and training in the way to combine with the cloud is woefully insufficient.”

- Identify Objectives: Determine what you want to achieve through PDM, such as improving efficiency, accuracy, or regulatory compliance.

- Choose Software: Select a PDM software that meets your business needs and budget. A cloud-based solution is preferred for scalability.

- Develop a Strategy: Create a plan that includes data collection, organization, and integration with existing systems.

- Train Employees: Train employees on how to use the software and follow best practices for data entry and management.

- Monitor and Evaluate Performance: Continuously monitor the performance of your PDM system, analyze data, and make improvements when necessary.

Frequently Asked Questions

What is the difference between PDM and PLM?

Product Data Management (PDM) focuses on managing product-related data whereas Product Lifecycle Management (PLM) manages the entire lifecycle of a product from conception to disposal.

Can I use PDM without specialized software?

You can manage product data without specialized software but using a software can automate many manual processes, reduce errors, and improve efficiency.

To be absolutely dedicated to safety means being keen to decide to the exhausting work. "What I've historically heard from most individuals is, 'We need to do it and never be disruptive'," Younger says. "These two issues simply do not go hand in hand as you implement tight safety. We have had the posh of getting executives...who imagine in safety first."

Hyperconvergence—combining storage, computing, and networking on a single {hardware} system—additionally performs an essential function in Ceridian's long-term technique. "Now we have a footprint in hyperconvergence with what we name our bureau panorama," Younger says. Hyperconvergence know-how guarantees to assist Ceridian unify its non-public, public, and distributed clouds, permitting the corporate to scale operations, simplify deployments, improve reliability, and decrease prices, amongst different advantages.

Can PDM be integrated with other business software?

Yes, PDM software can be integrated with other business software such as ERP, CRM, and inventory management systems for greater efficiency.

How does PDM help with regulatory compliance?

Maintaining accurate product information helps businesses comply with regulations and standards such as labeling requirements, safety guidelines, and environmental regulations.

Is PDM only useful for large businesses?

No, businesses of all sizes can benefit from PDM. Effective data management is crucial to make informed decisions, improve efficiency, and gain a competitive edge.

Conclusion

In conclusion, effective product data management can have a significant impact on your business’s success. It streamlines operations, improves efficiency, enhances customer experience, and ensures regulatory compliance. While there are alternatives to PDM, it’s the most effective solution for managing product data. By following the steps outlined in this article, you can implement an effective PDM system that meets your business needs.